Compactors for Paving: An In-Depth Guide

Introduction of Compactors for Paving

Overview of Compactors

Compactors are fundamental apparatus in the development business, intended to lessen the volume of soil, rock, and black-top, expanding their thickness through vibration, influence, or massaging activity. They are pivotal for making a steady and sturdy surface for streets, parking areas, and other cleared regions.

Importance in Paving

In paving, compactors guarantee that the base materials and the black-top layers are uniformly thick and without any trace of voids. This interaction is essential for the life span and burden bearing limit of the asphalt. Without appropriate compaction, cleared surfaces can experience the ill effects of untimely disappointments like breaks, potholes, and lopsidedness.

Historical Development

The idea of compaction has been around since old times when basic instruments like hand alters were utilized. Present day compactors have developed altogether, with headways in motor innovation, hydrodynamics, and materials science. The present compactors are more proficient, strong, and flexible, equipped for dealing with an extensive variety of paving applications.

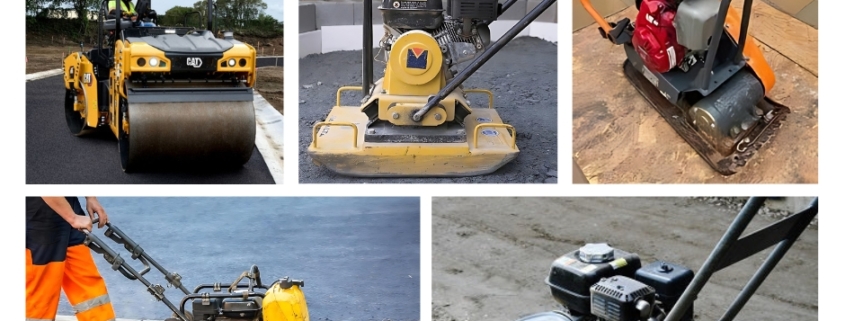

Types of Compactors for paving

Vibratory Plate Compactors for paving

Vibratory plate compactors are flexible and normally utilized for little to medium-sized paving projects. They work by creating high-recurrence vibrations that smaller the material underneath the plate.

Rammer or Jumping Jack Compactors

Rammers, otherwise called bouncing jack compactors, are great for compacting firm soils in restricted regions. They convey a high effect force, making them successful for channels and restricted spaces.

Road Rollers

Street rollers, or steamrollers, are uncompromising compactors utilized for huge scope paving projects. They come in different sorts, including single drum, twofold drum, and blend rollers, each appropriate for various compaction needs.

Sheepsfoot Rollers

Sheepsfoot rollers have a drum with projecting spikes, intended to conservative durable soils and dirt. They are generally utilized in earthwork and street development projects.

Pneumatic Rollers

Pneumatic rollers utilize elastic tires to ply and smaller the material. They give uniform strain appropriation, making them reasonable for black-top compaction and wrapping up.

Grid Rollers

Network rollers have a steel framework surface that compacts material through static strain. They are successful for pulverizing and compacting rough soils and totals.

compactor for paving

Technical Specifications Compactors for paving

Power Source

Compactors can be fueled by gas, diesel, or electric motors, each with its own arrangement of benefits and applications.

Engine Types

The motor kind impacts the compactor’s performance, eco-friendliness, and support needs. Normal motor sorts incorporate single-chamber and multi-chamber motors.

Compaction Force

Compaction force, estimated in pounds or newtons, decides the compactor’s capacity to densify materials. Higher compaction forces are required for harder materials.

Operating Weight

The working weight influences the compactor’s mobility and compaction profundity. Heavier compactors can accomplish further compaction however might be less dexterous.

Plate Size and Shape

The size and state of the compactor’s plate impact the inclusion region and compaction proficiency. Bigger plates cover more ground however might be less compelling in restricted spaces.

Vibration Frequency

Vibration recurrence, estimated in hertz, influences the compactor’s adequacy on various materials. Higher frequencies are better for granular soils, while lower frequencies suit strong soils.

compactor for paving

Applications Compactors for paving

Road Construction

Compactors are irreplaceable in street development, guaranteeing that the sub-base, base, and black-top layers are appropriately compacted for solidness and performance.

Parking Lots

In parking area development, compactors make a steady groundwork and smooth surface to help the heaviness of vehicles and forestall surface disintegration.

Driveways

For private and business carports, compactors guarantee a strong and, surprisingly, surface, upgrading the carport’s life expectancy and appearance.

Landscaping

In finishing projects, compactors are utilized to set up the ground for turf establishment, pathways, and holding walls, guaranteeing a steady and level surface.

Utility Trenches

Compactors are fundamental for refilling utility channels, forestalling future settling and keeping up with the trustworthiness of the encompassing surface.

Footings and Foundations

Legitimate compaction of soil underneath footings and establishments is critical for forestalling settlement and guaranteeing primary solidness.

Benefits of Using Compactors

Improved Surface Stability

Compactors increment the thickness of the material, making a steady surface that opposes moving and settling.

Increased Load-Bearing Capacity

Appropriately compacted surfaces can uphold heavier burdens, lessening the gamble of harm and deformation.

Enhanced Surface Smoothness

Compactors make a smooth and, surprisingly, surface, working on the appearance and usefulness of cleared regions.

Reduced Settling and Erosion

By wiping out voids and expanding thickness, compactors assist with forestalling settling and disintegration, broadening the existence of the asphalt.

Time and Labor Efficiency

Current compactors are intended for effectiveness, diminishing the time and work expected for compaction assignments and expanding in general efficiency.

compactor for paving

Challenges and Limitations

Soil Type Compatibility

Different compactors are appropriate for various soil types. Matching the right compactor to the dirt is significant for powerful compaction.

Noise and Vibration Concerns

Compactors create critical clamor and vibration, which can be problematic and may require moderation estimates in specific conditions.

Equipment Maintenance

Standard upkeep is crucial for keep compactors working proficiently. This incorporates motor upkeep, plate examination, and grease.

Cost Considerations

The underlying expense of compactors and the continuous upkeep costs can be huge, especially for top of the line models.

Latest Innovations in Compactor Technology

Smart Compaction Systems

Shrewd compaction frameworks use sensors and programming to screen and change compaction progressively, guaranteeing ideal performance and consistency.

Eco-Friendly Engines

Progressions in motor innovation have prompted the improvement of eco-accommodating motors that diminish outflows and fuel utilization.

GPS and Sensor Integration

GPS and sensor mix take into account exact compaction planning and quality control, working on the precision and proficiency of paving projects.

Autonomous Compactors

Independent compactors are furnished with cutting edge route and control frameworks, empowering them to work without human mediation, expanding security and productivity.

Future Prospects

Advancements in Autonomous Technology

The future of compactors remembers further progressions for independent innovation, making them more productive and lessening the requirement for human administrators.

Increased Efficiency and Precision

Progressing developments will keep on improving the productivity and accuracy of compactors, making them more powerful in a more extensive scope of utilizations.

Sustainability and Green Technology

Future compactors will progressively consolidate practical and green advances, diminishing their natural effect and working expenses.

Integration with Other Construction Technologies

Compactors will turn out to be more incorporated with other development advancements, like robots and man-made intelligence, to further develop by and large task effectiveness and quality.

compactor for paving

Comparative Analysis

Compactors vs. Other Paving Equipment

Compactors offer special benefits over other paving hardware, remembering higher compaction productivity and adaptability for various applications.

Benefits Over Manual Methods

Contrasted with manual compaction strategies, compactors give predominant performance, consistency, and speed, making them irreplaceable for present day paving projects.

Cost Comparison

While compactors address a huge speculation, their advantages regarding proficiency, solidness, and quality frequently legitimize the expense contrasted with manual strategies or less high level hardware.

User Guides and Tutorials

How to Choose the Right Compactor

Picking the right compactor includes considering elements, for example, the sort of material, project size, and explicit compaction necessities. Talking with specialists and checking on producer determinations can assist with pursuing an informed choice.

Safety Tips for Operating Compactors

Security is fundamental while working compactors. Administrators ought to wear defensive stuff, keep maker rules, and know about their environmental factors to forestall mishaps.

Maintenance and Care Guidelines

Ordinary upkeep is fundamental for keeping compactors in ideal condition. This incorporates routine assessments, opportune fixes, and appropriate stockpiling.

Troubleshooting Common Issues

Normal issues with compactors incorporate motor issues, vibration inconsistencies, and plate harm. Investigating these issues frequently includes really taking a look at the fuel, reviewing the vibration framework, and supplanting worn parts.

compactor for paving

Personal Stories and Case Studies

Successful Road Projects

Various street projects have effectively used compactors to accomplish superior grade, sturdy surfaces. These contextual analyses feature the significance of legitimate compaction in project achievement.

Challenges in Harsh Environments

Compactors have demonstrated their adequacy in testing conditions, for example, outrageous temperatures and troublesome soil conditions, showing their flexibility and unwavering quality.

Innovations Leading to Success

Imaginative advancements, like shrewd compaction frameworks and independent compactors, have prompted huge upgrades in paving project results, exhibiting the capability of cutting edge compaction gear.

Expert Insights

Quotes from Industry Leaders

Industry pioneers stress the basic job of compactors in accomplishing strong and excellent asphalts, featuring their effect on project achievement and long haul performance.

Recommendations from Civil Engineers

Structural specialists suggest utilizing the right sort of compactor for explicit applications and underscore the significance of normal upkeep and administrator preparing.

Insights from Manufacturers

Makers give significant bits of knowledge into the most recent mechanical progressions and best practices for amplifying the performance and life span of compactors.

Conclusion

Summary of Key Points

Compactors are fundamental devices in the paving business, offering various advantages like better surface solidness, expanded load-bearing limit, and improved effectiveness. Understanding the various kinds of compactors, their applications, and the furthest down the line mechanical headways can assist with guaranteeing effective paving projects.

Future Outlook for Paving Compactors

The fate of paving compactors looks encouraging, with continuous progressions in independent innovation, eco-accommodating motors, and brilliant compaction frameworks set to change the business.

Call to Action for Further Education

For more information on compactors and their applications, counsel industry specialists, audit producer assets, and remain refreshed on the most recent mechanical turns of events.

Leave a Reply

Want to join the discussion?Feel free to contribute!