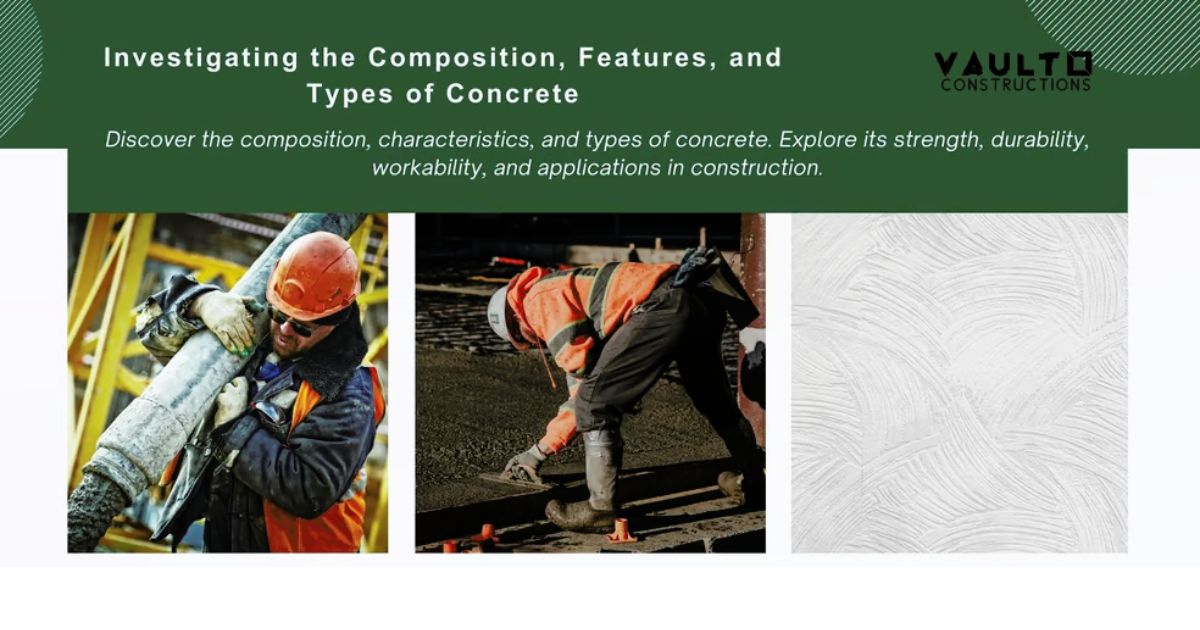

Investigating the Composition, Features, and Types of Concrete

Our modern infrastructure is supported by concrete, a material that is widely used in buildings. Understanding concrete’s composition and properties is crucial for appreciating its adaptability and variety of uses. The essential characteristics of concrete are examined in this article, along with its composition, qualities, and the variables affecting how well it performs.

Composition of Concrete

Concrete is made up of three main ingredients: cement, aggregates, and water. Concrete is a composite material. The other elements are held together with cement, which serves as a binder. Sand, gravel, crushed stone, or recycled materials are examples of aggregates that give the concrete mixture bulk and stability. The hydration process is started by adding water, which causes the cement to chemically react and solidify.

Features of Concrete

A common building material, concrete has a number of essential qualities that make it appropriate for a range of uses. Engineers, architects, and construction experts must comprehend these features in order to design and build long-lasting, effective structures. The following are some of the primary qualities of concrete:

Structural integrity: Concrete has exceptional compressive strength, which enables it to support heavy loads without suffering substantial deformation or failure. Compressive strength, which is determined by the ratios of cement, aggregates, water, and curing conditions, is commonly used to quantify the strength of concrete. Concrete may endure tension stresses by being reinforced with steel bars, which increases its strength.

Robustness: Concrete is renowned for its robustness and lengthy service life. Extreme environmental conditions, such as exposure to moisture, chemicals, and heat, are not a problem for it. Concrete can be made more durable and resistant to corrosion, degradation, and cracking by using the right mix design, appropriate curing, and additives.

Workability: During construction, workability relates to how simple it is to mix, pour, and finish concrete. Concrete’s workability is regulated by a number of elements, including the amount of water present, the size and shape of the aggregate, and chemical admixtures. Concrete that is at its most workable can be easily shaped and placed in the proper form without segregation or excessive water bleeding.

Density: Concrete’s weight and structural stability are aided by its comparatively high density. Depending on the kind and quantity of particles used, concrete’s density might change. When more strength and bulk are needed, such as in heavy-duty constructions or radiation shielding, higher-density concrete is frequently employed.

Sound Insulation: Concrete is a great material for noise reduction because it has good sound insulation qualities. It contributes to an indoor environment that is quieter by reducing the transmission of impact and airborne sound. This quality is very useful in residential, commercial, and educational structures.

Fire resistance: Concrete has great fire resistance, which offers passive fire protection to buildings. It can resist high temperatures without losing the integrity of its structure. The slow rate of heat transfer through concrete aids in the containment of fires and buys crucial time for residents to safely evacuate.

Versatility in terms of appearance: Concrete gives a variety of options for looks and finishes. Architects and designers have creative freedom with it because it can be cast into a variety of shapes, textures, and colors. Concrete can be finished in a variety of ways, from polished and smooth surfaces to textured or exposed aggregate surfaces, allowing for a variety of architectural interpretations.

Elements That Affect Concrete Performance

The ratios of cement, aggregates, water, and any other additions are essential in determining the qualities of concrete. a. Mix design. According to the needs of the project, the mix design is customized, taking intended strength, durability, and workability into account.

a. Curing: Concrete’s strength and durability are greatly enhanced by proper curing. Early on in the hydration process, proper moisture and temperature control encourage complete cement hydration and guard against cracking.

b. Admixtures: To change the properties of concrete, chemical admixtures are added. These additives may improve strength, decrease water content, increase workability, or offer particular properties like air entrainment or water resistance.

c. Aggregates: The strength, longevity, and look of concrete are substantially influenced by the choice and quality of aggregates. The overall effectiveness of the concrete mixture is influenced by the use of well-graded aggregates with the right particle sizes and characteristics.

Types Of Concrete

Concrete is a flexible building material that may be customized to fit unique project needs. Concrete comes in a variety of forms to accommodate various construction requirements, environmental factors, and applications. Engineers and construction experts can choose the best concrete type for their projects by being aware of the various forms of concrete. Here are some types of concrete that are frequently used:

1. Normal Strength Concrete: The most often used kind of concrete is normal strength concrete, usually referred to as plain or traditional concrete. Compressive strength typically ranges from 10 to 40 megapascals (MPa). For a variety of general building tasks, such as foundations, slabs, beams, columns, and walls, normal-strength concrete is appropriate.

2. High-Strength Concrete: Compared to regular-strength concrete, high-strength concrete is developed to attain a much higher compressive strength. It usually has a compressive strength of at least 40 MPa and a maximum of 100 MPa. In applications requiring more structural integrity and load-bearing capabilities, such as high-rise buildings, bridges, and heavy-duty industrial structures, high-strength concrete is employed.

3. Lightweight Concrete: Compared to regular concrete, lightweight concrete is made to have a lower density. It is accomplished by adding lightweight aggregates to the concrete mixture, such as expanded shale, clay, or slate. Concrete that is lighter in weight has benefits like better insulation, fewer dead loads on structures, and increased workability. In applications where weight reduction is desired, including precast panels, roof decks, and insulating blocks, it is frequently employed.

4. Decorative concrete: This type of concrete emphasises the attractive features of the material. It comprises a range of methods and treatments that improve the concrete surface’s look. Concrete that has been decorated using various processes, including stamping, staining, exposing aggregate, polishing, and textured finishes. It is applied in situations where aesthetics are important, like architectural details, walks, patios, and interior floors.

5. Precast Concrete: Precast concrete is a term used to describe concrete components that are made in a controlled environment before being delivered to the construction site and installed there. Beams, columns, wall panels, slabs, and other specialized components are examples of precast elements. Improved quality control, quicker construction, less on-site labor, and increased durability are some benefits of precast concrete.

Conclusion

In conclusion, investigating the components, traits, and varieties of concrete reveals its enormous potential as a building material. We can build resilient and sustainable structures that will influence our built environment for future generations by utilizing its strength, durability, use, and aesthetic potential. Concrete continues to be an essential component of contemporary construction, enabling us to lay the groundwork for a better future.

Leave a Reply

Want to join the discussion?Feel free to contribute!