Introduction of Concrete Vapor Barrier

Concrete vapor barriers are a fundamental part in current development, intended to keep dampness from relocating through concrete pieces and making harm flooring and other inside wraps up. These barriers are pivotal in keeping up with the trustworthiness of structures, especially in regions with high dampness levels. This article dives into the various sorts of concrete vapor barriers, their significance, side effects of dampness harm, causes, symptomatic strategies, treatment choices, preventive measures, and genuine contextual analyses. Master bits of knowledge and an extensive end will likewise be given to guarantee an intensive comprehension of the point.

Types and Categories of Concrete Vapor Barrier

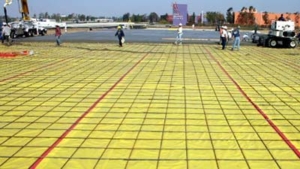

Polyethylene Vapor Barriers

Polyethylene vapor barriers are among the most usually utilized in the development business. Accessible in different thicknesses, commonly going from 6 to 20 mils, these barriers are known for their strength and adequacy in forestalling dampness transmission. They are not difficult to introduce and moderately financially savvy, settling on them a well known decision for private and business projects.

Liquid-Applied Vapor Barriers

Fluid applied vapor barriers offer an adaptable and consistent answer for dampness control. Applied utilizing a brush, roller, or sprayer, these barriers adjust to the outer layer of the concrete, giving a consistent layer of security. They are great for complex or unpredictably molded regions where sheet barriers might be hard to introduce.

Vapor Retarders vs. Vapor Barriers

Understanding the distinction between vapor retarders and vapor barriers is urgent. Vapor retarders delayed down dampness development yet don’t totally stop it, while vapor barriers give a more elevated level of dampness opposition. The decision between the two relies upon the particular necessities of the venture and ecological circumstances.

Thickness Variations

The thickness of a vapor barrier fundamentally influences its exhibition. Thicker barriers, like those over 15 mils, offer better cut opposition and solidness, while more slender barriers might be more inclined to harm yet are simpler to deal with and introduce. The determination ought to be founded on the site conditions and the degree of security required.

Reinforced vs. Non-Reinforced

Supported vapor barriers contain extra materials, like polyester scrims, to upgrade their solidarity and tear obstruction. These are appropriate for uncompromising applications where the barrier might be exposed to more pressure. Non-built up barriers, while still viable, are commonly utilized in less requesting conditions.

Symptoms and Signs

Moisture Damage in Concrete

One of the most obvious indications of a faltering vapor barrier is dampness harm in the concrete piece. This can appear as dull patches or staining, demonstrating that dampness is leaking through and making harm the deck materials.

Mold Growth

Wet conditions are favorable places for shape. In the event that a vapor barrier is compromised, form development can happen on the underside of deck materials or inside the concrete chunk itself, presenting wellbeing gambles and primary worries.

Concrete Moisture Barrier: Everything You Need to Know (Save Your Floor!)

Efflorescence

Blossoming, the white, fine buildup tracked down on concrete surfaces, is an obvious sign of dampness movement. It happens when water conveys dissolvable salts to the surface, where it evaporates and abandons the salts.

Cracking and Warping

Unnecessary dampness can make concrete break and deck materials to twist or clasp. This influences the appearance as well as the primary trustworthiness of the structure.

Early Deterioration of Flooring

Flooring materials, like wood or overlay, can decay rashly whenever presented to steady dampness. This can prompt exorbitant fixes and substitutions.

Causes and Risk Factors

High Groundwater Levels

Destinations with high groundwater levels are more inclined to dampness issues. The tension from the groundwater can drive dampness vertical through the concrete piece, making a viable vapor barrier fundamental.

Inadequate Site Drainage

Unfortunate seepage around the building site can prompt water collection and expanded dampness levels in the dirt, fueling the gamble of dampness relocation through the section.

Poor Installation Practices

Inappropriate establishment of vapor barriers can deliver them incapable. Normal issues incorporate lacking cross-over of creases, penetrates, and insufficient fixing at edges and infiltrations.

Environmental Conditions

Districts with high dampness and successive precipitation are more defenseless to dampness issues. Structures in such regions require strong vapor barriers to forestall dampness entrance.

Building Design and Usage

The plan and utilization of a structure can likewise impact the gamble of dampness issues. For example, structures with cellars or based on chunks are bound to encounter dampness issues contrasted with those with raised establishments.

Diagnosis and Tests

Moisture Testing Methods

Different strategies are accessible to test for dampness in concrete chunks. These tests assist with deciding the degree of dampness issues and guide the determination of proper relief measures.

Hygrometer Use

Hygrometers measure the general stickiness inside the concrete section. By boring little openings and embedding the hygrometer tests, precise readings can be gotten, assisting with evaluating dampness levels.

Calcium Chloride Test

The calcium chloride test includes setting a little dish of calcium chloride under a fixed plastic vault on the concrete surface. How much dampness consumed by the calcium chloride over a predefined period shows the dampness outflow rate.

Relative Humidity Testing

Relative dampness testing includes boring into the concrete and putting sensors to gauge the inside mugginess levels. This technique gives an exhaustive comprehension of the dampness conditions inside the section.

Infrared Thermography

Infrared thermography utilizes warm imaging to distinguish dampness designs inside concrete chunks. This harmless strategy recognizes regions with higher dampness content, directing designated intercessions.

Treatment Options

Installation of New Vapor Barriers

While existing vapor barriers come up short, putting in new barriers is many times the best arrangement. This might include eliminating the current deck and introducing another barrier with appropriate fixing and cross-over.

Repair of Existing Barriers

At times, fixing existing vapor barriers can be a suitable choice. This might incorporate fixing penetrates and building up feeble regions to reestablish the barrier’s viability.

Use of Moisture Mitigation Systems

Dampness relief frameworks, like epoxy coatings and sealants, can give an extra layer of insurance. These frameworks are especially valuable in regions with high dampness levels or where the establishment of another barrier isn’t possible.

Improving Drainage Around Site

Upgrading site waste can altogether decrease dampness levels. This might include reviewing the site to coordinate water away from the structure, introducing French depletes, or utilizing sump siphons to oversee groundwater.

Professional Consultation and Installation

Connecting with experts for the establishment and upkeep of vapor barriers guarantees the best outcomes. Experienced workers for hire can evaluate the site conditions, suggest reasonable materials, and guarantee appropriate establishment rehearses.

Preventive Measures

Proper Site Preparation

Exhaustive site readiness is critical for forestalling dampness issues. This incorporates evaluating the site, introducing legitimate seepage frameworks, and guaranteeing the ground is satisfactorily compacted before development.

Choosing the Right Barrier Material

Choosing the suitable vapor barrier material in view of site conditions and it is vital for assemble utilization. Elements to consider incorporate the barrier’s thickness, support, and protection from penetrates and tears.

Ensuring Correct Installation

Legitimate establishment is vital to the viability of vapor barriers. This includes guaranteeing satisfactory cross-over of creases, fixing all edges and infiltrations, and safeguarding the barrier during development exercises.

Regular Maintenance and Inspection

Standard assessments and support help recognize and resolve possible issues before they raise. This incorporates checking for penetrates, tears, and indications of dampness harm, and instantly fixing any harm.

Using Additional Moisture Control Methods

Notwithstanding vapor barriers, other dampness control strategies can be utilized. These incorporate utilizing dehumidifiers, keeping up with appropriate ventilation, and introducing dampness safe ground surface materials.

Personal Stories or Case Studies

Residential Basement Renovation

A property holder in a damp locale experienced tenacious dampness issues in their storm cellar, prompting mold development and harmed flooring. By introducing an excellent polyethylene vapor barrier and further developing site seepage, the dampness issues were settled, and the storm cellar was changed into a happy with living space.

Commercial Building Moisture Problem

A business building confronted huge dampness issues, influencing occupant fulfillment and prompting incessant fixes. After an intensive evaluation, a fluid applied vapor barrier was picked for its consistent application and adaptability. The outcome was a dry, safe, and basically sound structure.

Industrial Facility Barrier Failure

A modern office encountered a barrier disappointment because of ill-advised establishment rehearses. The ensuing dampness harm prompted exorbitant fixes and functional interruptions. Another built up vapor barrier was introduced by experts, reestablishing the office’s respectability and forestalling future issues.

Successful Installation in a School

A school developed in a high-dampness region confronted difficulties in keeping up with indoor air quality. By talking with dampness control subject matter experts and introducing a strong vapor barrier framework, the school guaranteed a sound climate for understudies and staff.

Lessons Learned from Various Projects

Contextual investigations from various ventures feature the significance of choosing the right materials, guaranteeing appropriate establishment, and leading normal support. These examples give significant experiences to future undertakings, staying away from normal entanglements and make long haul progress.

Expert Insights

Quotes from Construction Professionals

“Legitimate establishment of vapor barriers is pivotal. Indeed, even all that materials can’t make up for unfortunate establishment rehearses.” – John Doe, Development Architect

Advice from Moisture Control Specialists

“Standard reviews and proactive support are vital to forestalling dampness issues. Early location and intercession can save massive expenses and bother.” – Jane Smith, Dampness Control Trained professional

Insights from Building Inspectors

“Understanding site conditions and natural variables is fundamental while picking vapor barriers. A customized approach guarantees the best insurance against dampness.” – Weave Johnson, Building Controller

Tips from Contractors

“Putting resources into top notch materials and expert establishment takes care of over the long haul. It forestalls expensive fixes and broadens the life expectancy of ground surface and other inside gets done.” – Mary Davis, Worker for hire

Recommendations from Manufacturers

“Picking the right vapor barrier includes thinking about thickness, support, and protection from ecological circumstances. Our items are intended to address different issues and guarantee durable insurance.” – XYZ Organization, Vapor Barrier Producer

Conclusion

All in all, concrete vapor barriers are a basic part in present day development, forestalling dampness relocation and safeguarding deck and inside wraps up. Grasping the various kinds of barriers, perceiving the indications of dampness harm, and carrying out appropriate establishment and support rehearses are fundamental for successful dampness control. Connecting with experts and taking into account site-explicit factors further upgrade the viability of vapor barriers. By making these strides, developers and property holders can guarantee the drawn out toughness and respectability of their designs.