What is Concrete Ratio?

Concrete ratio alludes to the extent of the components in a concrete mix. Regularly, the ratio is communicated regarding the general volumes of concrete, sand, rock (or total), and water. The correct ratio guarantees that the concrete mix has the ideal properties for its specific application.

Importance of Correct Concrete Ratio

Strength and Sturdiness

An even concrete ratio is significant for the strength and solidness of the construction. To an extreme or excessively bit of any part can debilitate the concrete, making it defenseless to breaking, contracting, or different forms of primary disappointment.

Usefulness

The functionality of concrete alludes to the fact that it is so natural to mix, transport, spot, and finish. A legitimate ratio guarantees that the concrete is neither too wet nor excessively dry, which is fundamental for accomplishing a smooth and level surface.

Cost Effectiveness

Utilizing the right extents can likewise be practical. Abusing concrete, for example, can altogether inflate costs, while underusing it could prompt powerless concrete that requires fixes or substitution.

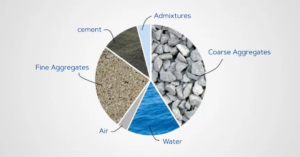

Components of Concrete Mix

Concrete

Concrete goes about as the limiting specialist in concrete. It responds with water to form a glue that covers the totals and makes up for the shortfalls in the mix.

Sand

Sand, or fine total, fills the holes between the bigger totals and helps make the concrete mixture more conservative.

Rock

Rock, or coarse total, gives the strength expected to the concrete. It is the heft of the concrete mix.

Water

Water enacts the concrete and helps stuck the totals. The amount of water impacts the usefulness and strength of the concrete.

Added substances and Admixtures

Added substances, for example, fly debris, silica smoke, and admixtures like plasticizers, retarders, and gas pedals can be added to adjust the properties of concrete to suit specific prerequisites.

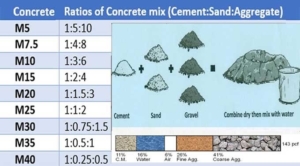

Types of Concrete Ratios

Ostensible Mix

Ostensible mixes are predefined mix ratios that are for the most part reasonable for limited scope development projects. They depend on previous encounters and are not custom-made to specific necessities.

Configuration Mix

Configuration mixes are custom fitted to meet the specific necessities of an undertaking. They depend on the ideal properties of the finished concrete, like strength, toughness, and usefulness.

Standard Concrete Ratios

M5, M7.5, M10, M15

These mixes are reasonable for limited scope, non-underlying applications. They have lower compressive strength contrasted with higher grades.

M20, M25, M30, M35

These mixes are utilized in primary applications like bars, sections, and columns. They offer higher strength and sturdiness.

High-strength mixes (M40, M45, M50, and so on.)

These mixes are utilized in high-load-bearing applications like extensions, tall structures, and other basic designs. They offer extremely high strength and solidness.

Calculating Concrete Ratio

Step-by-Step Calculation Method

To work out the concrete ratio, follow these steps:

- Determine the expected strength and usefulness.

- Select the proper mix ratio in view of the strength.

- Calculate the amounts of every part required.

- Adjust for ecological circumstances and specific venture needs.

Devices and Software for Calculation

Different apparatuses and software, for example, concrete mix plan adding machines and accounting sheets, can work on the method involved with deciding the correct concrete ratio.

Factors Affecting Concrete Ratio

Natural Circumstances

Temperature, stickiness, and openness to synthetic compounds or marine conditions can influence the concrete mix. Changes might be important to guarantee solidness.

Sort of Development

The sort of development, whether it’s an establishment, segment, or piece, impacts the expected concrete ratio.

Material Quality

The nature of the unrefined components utilized (concrete, sand, rock) likewise influences the concrete mix. Better materials can bring about more grounded concrete.

Mixing Concrete

Hand Mixing

Hand mixing is appropriate for little tasks. It includes physically consolidating the components utilizing devices like digging tools and cultivators.

Machine Mixing

Machine mixing is utilized for bigger activities. It guarantees a more uniform and effective mix and is commonly done utilizing concrete mixers.

Testing Concrete Mix

Droop Test

The downturn test estimates the functionality of new concrete. A standard cone is loaded up with concrete, and the rut (drop in level) is estimated in the wake of eliminating the cone.

Compressive Strength Test

This test decides the concrete’s capacity to endure loads. Barrel shaped examples are exposed to expanding tension until they fizzle.

Other Testing Methods

Different tests incorporate the air content test, water penetrability test, and flexural strength test, each giving significant information about the concrete’s properties.

Adjusting Concrete Mix

Normal Changes

Normal changes incorporate adding more water for expanded usefulness or greater concrete for higher strength. The utilization of admixtures can likewise help in accomplishing wanted properties.

Investigating Mix Issues

Issues like isolation, dying, or unfortunate functionality can be tended to by adjusting the extents or adding reasonable admixtures.

Concrete Ratio for Specific Applications

Establishments

Establishments require major areas of strength for a strong mix to help the heap of the design above. Commonly, higher-strength mixes (M20 or more) are utilized.

Chunks

Concrete sections require a mix that gives a smooth finish and sufficient strength. M15 to M25 mixes are usually utilized.

Columns

Columns bear huge primary loads and require high-strength concrete (M25 or more) to guarantee solidness.

Radiates

Radiates support loads from chunks and other primary components. They ordinarily require mixes in the scope of M25 to M30.

Preventive Measures

Relieving Strategies

Legitimate restoring is fundamental to guarantee that concrete accomplishes its original capacity. Methods incorporate keeping the surface moist and covering it with restoring mixtures or wet burlap.

Safeguarding from Atmospheric conditions

Shielding concrete from outrageous atmospheric conditions, like frigid temperatures or exorbitant intensity, is urgent to forestall breaking and guarantee appropriate restoring.

Master Bits of knowledge

Tips from Structural Specialists

Structural designers suggest utilizing a very much reviewed total mix and keeping up with the water-concrete ratio to guarantee solid and sturdy concrete.

Advancements in Concrete Mix Plan

Ongoing developments incorporate the utilization of self-compacting concrete, superior performance concrete, and the incorporation of reused materials to further develop maintainability.

Genuine Contextual investigations

Effective Tasks

Contextual analyses of effective activities feature the importance of utilizing the correct concrete ratio and legitimate mixing procedures.

Illustrations Gained from Disappointments

Examining disappointments can give important bits of knowledge into normal mistakes and how to stay away from them in later ventures.

Future Patterns in Concrete Mix Plan

Supportable Concrete

The push for manageability has prompted the advancement of eco-accommodating concrete mixes that consolidate reused materials and diminish carbon impressions.

High level Admixtures

New admixtures are being created to upgrade concrete properties, like strength, solidness, and functionality, while decreasing ecological effect.

conclusion

Understanding and utilizing the correct concrete ratio is vital for the progress of any development project. It guarantees strength, sturdiness, and cost-proficiency. By following prescribed procedures and remaining refreshed with the most recent developments, manufacturers can accomplish ideal outcomes in their concrete designs.