Introduction of Drill Presses

A drill press, otherwise called a point of support drill, is a flexible device utilized in carpentry, metalworking, and other accuracy errands. Its capacity to drill exact and predictable openings makes it a fundamental device in studios and businesses. This article explores the various pieces of drill presses, including their sorts, features, usages, backing, and that is only the start.

What is a Drill Press?

A drill press is a fixed, power-driven machine planned for exactness drilling. Unlike hand-held drills, a drill press offers more imperative control, accuracy, and strength.It comprises of a base, section, table, shaft, throw, and engine, which cooperate to guarantee exact drilling.

History of Drill Presses

The drill press has advanced fundamentally since its initiation. Early adaptations were physically worked and utilized in antiquated developments for carpentry and metalworking. The Modern Upheaval presented steam-controlled drill presses, trailed by electrically fueled adaptations in the twentieth 100 years. Current drill presses consolidate progressed highlights like variable speed control and computerized readouts.

Types of Drill Presses

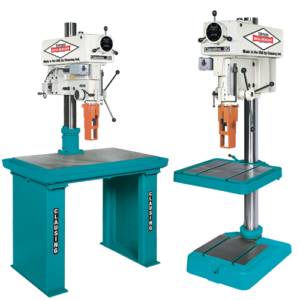

Bench Drill Press

A seat drill press is a conservative model intended to be mounted on a workbench. It is great for little to medium-sized projects and is famous among specialists and little studios.

Floor Drill Press

Bigger and more remarkable than seat models, floor drill presses are detached units appropriate for substantial assignments. They offer more noteworthy drilling profundity and limit, making them appropriate for modern use.

Radial Drill Press

The outspread drill press includes a flexible arm that stretches out over the workpiece, taking into account drilling at different points and positions. This adaptability makes it ideal for intricate and enormous scope projects.

Magnetic Drill Press

An attractive drill press, or mag drill, is intended for drilling in metal. It utilizes a strong magnet to stick to the metal surface, giving solidness and accuracy. It is generally utilized in development and manufacture businesses.

Mini Drill Press

A little drill press is a more modest variant of the seat drill press, intended for accuracy work on little parts. It is many times utilized in adornments making, model structure, and gadgets.

Key Parts of a Drill Press

Base

The base gives dependability and backing to the whole drill press. It is normally made of solid metal or steel to guarantee a strong groundwork.

Column

The segment is an upward help structure that interfaces the base to the top of the drill press. It guarantees arrangement and steadiness during drilling tasks.

Table

The table backings the workpiece and can be adapted to level and point. It frequently includes openings for bracing adornments and apparatuses.

Spindle

The axle is a pivoting shaft that holds the drill bit. It is driven by the engine and sends the drilling power to the workpiece.

Chuck

The hurl is a cinching gadget that holds the drill bit set up. It is movable to oblige different piece sizes and types.

Motor

The engine drives the shaft and decides the drilling rate and power. Engines change in drive and speed settings, influencing the exhibition of the drill press.

Technical Specifications

While picking a drill press, it’s critical to consider determinations, for example,

- Engine Power: Normally estimated in drive (HP), influencing the drilling ability.

- Speed Reach: The scope of rates the drill press can work at, generally estimated in RPM (cycles each moment).

- Drilling Limit: The greatest distance across of the opening the drill press can deal with.

- Throat Profundity: The separation from the axle to the section, deciding the most extreme width of the workpiece.

- Table Size and Movability: The elements of the table and its capacity to shift and move upward.

How to Choose the Right Drill Press

Consider the Purpose

Distinguish whether you really want the drill press for carpentry, metalworking, or different assignments. Various models are intended to effectively deal with explicit materials and assignments.

Evaluate the Size and Power

Pick a size and power rating that matches the size of your undertakings. For hard core modern undertakings, a story drill press with a powerful engine is great, though a seat or scaled down drill press does the trick for more modest, accuracy work.

Check the Speed Options

A drill press with variable speed settings gives flexibility to various materials and drilling prerequisites. Guarantee the model you pick can change velocities to match your requirements.

Look at the Build Quality

Put resources into a drill press with a durable development. Parts produced using cast iron or steel guarantee sturdiness and solidness, upgrading the machine’s life expectancy and execution.

Setting Up Your Drill Press

Safety Precautions

Prior to setting up your drill press, guarantee you have wellbeing gear, including security glasses, gloves, and ear insurance. Peruse the producer’s manual completely to figure out the particular arrangement and wellbeing directions.

Assembly Instructions

- Unpack the Drill Press: Cautiously unload all parts and check for harm.

- Assemble the Base and Section: Join the segment to the base utilizing the gave bolts.

- Install the Table: Append the table to the section, guaranteeing it can drop openly all over the place.

- Mount the Head: Secure the head unit, which contains the engine and axle, to the highest point of the section.

- Attach the Throw: Introduce the hurl onto the shaft and guarantee it is firmly gotten.

- Test the Development: Check that the axle moves without a hitch and that the table changes accurately.

Operating a Drill Press

Basic Drilling Techniques

- Select the Drill Touch: Pick a piece reasonable for your material and wanted opening size.

- Adjust the Table: Put everything out on the table to the fitting level and plot for your workpiece.

- Secure the Workpiece: Cinch the workpiece immovably to the table to forestall development.

- Set the Speed: Change the drill press speed as per the material and touch size.

- Start Drilling: Lower the shaft gradually, applying consistent pressure to drill the opening.

Advanced Drilling Techniques

High level strategies incorporate calculated drilling, making huge openings with opening saws, and involving extraordinary pieces for explicit errands, for example, subsetting or mortising. Understanding these procedures grows the drill press’ adaptability.

Using Different Drill Bits

Different drill pieces are intended for explicit materials and purposes. For instance, wind pieces are normal for universally useful drilling, while Forstner pieces are great for making level lined openings in wood. Choosing the right piece is vital for accomplishing wanted results.

Maintenance and Care

Routine Maintenance

- Clean Routinely: Eliminate residue and flotsam and jetsam from the machine after each utilization.

- Lubricate Moving Parts: Guarantee every single moving part, like the axle and table changes, are very much greased up.

- Check for Wear: Review belts, orientation, and different parts routinely for indications of wear and supplant them depending on the situation.

- Align the Table and Axle: Consistently check and change the arrangement to keep up with drilling exactness.

Troubleshooting Common Issues

Normal issues incorporate engine issues, axle wobble, and skewed tables. Address these by:

- Check the power supply and engine associations. Supplant defective engines.

- Engine Issues: Axle Wobble: Fix the hurl and investigate the shaft orientation.

- Skewed Table: Change the table braces and rushes to realign the table.

Safety Tips

- Continuously Wear Wellbeing Stuff: Use security glasses, gloves, and ear assurance.

- Secure the Workpiece: Guarantee the workpiece is cinched safely to forestall development.

- Keep Hands Clear: Get your hands far from the turning drill bit.

- Switch Off While Changing: Consistently switch off the drill press prior to making any changes.

Advantages of Utilizing a Drill Press

Drill presses offer various advantages, including:

- Accuracy: Accomplish exact, reliable openings effortlessly.

- Power: Handle intense materials with high-power engines.

- Flexibility: Play out many drilling errands with different pieces and settings.

- Security: Guarantee steady, controlled drilling with a strong base and segment.

Challenges and Limitations

Regardless of its benefits, a drill press has restrictions, for example,

- Space Necessities: Bigger models require critical studio space.

- Introductory Expense: Excellent drill presses can be costly.

- Expectation to absorb information: Dominating high level procedures requires practice and expertise.

Developments in Drill Press Innovation

Late advancements incorporate computerized speed controls, laser guides for exact drilling, and programmed feed systems. These headways improve the drill press’ ease of use and exactness, making it a significant instrument for current studios.

Future Possibilities

The eventual fate of drill presses lies in expanded mechanization and combination with shrewd innovation. Advancements, for example, IoT-empowered drill presses and artificial intelligence driven accuracy changes are supposed to upset the business.

Contrasting Drill Presses with Other Drilling Instruments

Contrasted with hand-held drills and other drilling instruments, drill presses offer prevalent accuracy, power, and strength. Nonetheless, they are less versatile and require a devoted space.

Client Audits and Tributes

Clients acclaim drill presses for their exactness, power, and flexibility. Normal criticism features their capacity to deal with different assignments effectively and the huge improvement in work quality contrasted with manual drilling techniques.

FAQs About Drill Presses

Q: What is the distinction between a seat and a story drill press?

A: Seat drill presses are minimal and mounted on a workbench, reasonable for little undertakings. Floor drill presses are bigger, unsupported units intended for hard core assignments.

Q: How would I keep up with my drill press?

A: Consistently spotless, grease up, and review parts for wear. Adjust the table and shaft to guarantee exactness.

Q: Might a drill at any point press be utilized for metals and wood?

A: Indeed, with proper drill pieces and settings, a drill press can deal with the two metals and wood.

Q: What security safeguards would it be a good idea for me to take while utilizing a drill press?

A: Wear wellbeing gear, secure the workpiece, keep hands clear of the digit, and mood killer the machine before changes.

Conclusion

A drill press is an important device for accuracy drilling in different materials. Grasping its parts, types, and legitimate activity guarantees proficient and safe use. With progressions in innovation, drill presses keep on developing, offering more prominent precision and accommodation for clients. Putting resources into a top notch drill press upgrades your studio’s capacities, making complex errands simpler and more effective.