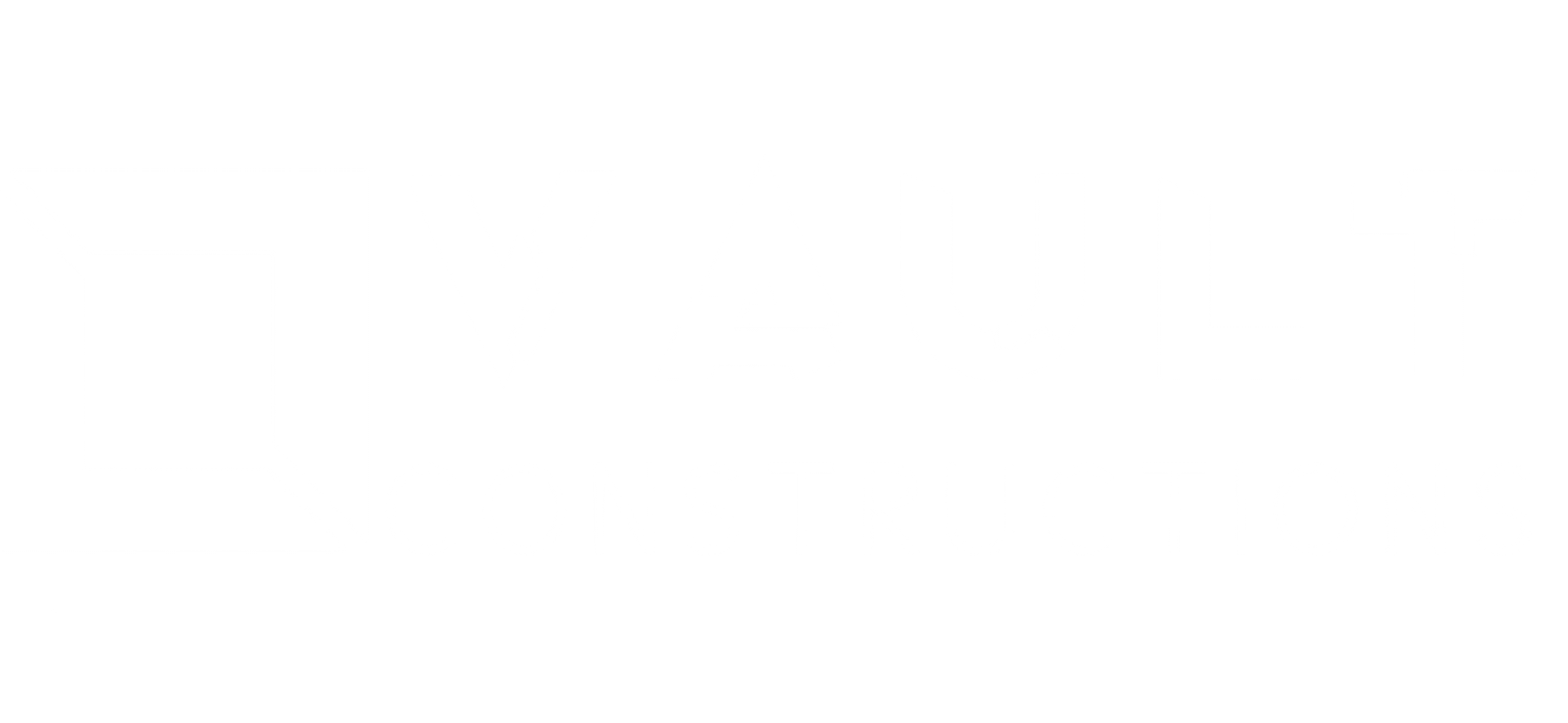

Introduction of airtight inspection cover

Airtight inspection covers are fundamental parts in different businesses, guaranteeing the protected and proficient activity of gear and frameworks. They are utilized to seal openings in tanks, vessels, and lines, forestalling the departure of gases, fluids, or pollutants. This article dives into the complexities of airtight inspection covers, featuring their importance, types, establishment techniques, and upkeep rehearses.

Concrete Retaining Wall Blocks: Comprehensive Guide

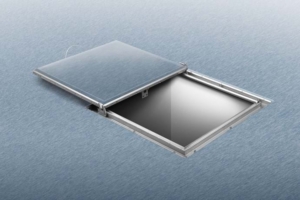

Technical Specifications

Material Composition

- Tempered steel

- Aluminum

- Composite materials

- Elastic gaskets

Design Features

- Catapulted or pivoted systems

- Fixing components

- Pressure appraisals

Manufacturing Standards

- ISO 9001

- ASME norms

- Programming interface determinations

Airtight Inspection Covers

Applications

Industrial Use

- Oil and gas processing plants

- Synthetic plants

- Power age offices

Marine Applications

- Transport bodies

- Submarines

- Seaward stages

Residential and Commercial Use

- Air conditioning frameworks

- Water tanks

- Squander the executives frameworks

-

Airtight Inspection Covers

Benefits

Safety Enhancements

- Forestalls breaks and spills

- Lessens chance of pollution

- Guarantees administrative consistence

Operational Efficiency

- Simple access for support and inspection

- Solid and enduring

- Adaptable for different applications

Challenges and Limitations

Installation Complexity

- Requires exact fitting

- Needs talented work

- Potential for beginning significant expenses

Maintenance Issues

- Standard inspection required

- Substitution of gaskets and seals

- Potential for consumption in unforgiving conditions

Latest Innovations

Advanced Materials

- Utilization of carbon fiber composites

- Advancement of erosion safe combinations

Smart Inspection Covers

- Combination of sensors for ongoing observing

- Mechanized locking and opening components

Future Prospects

Technological Advancements

- Further developed fixing advancements

- Improved material toughness

Industry Trends

- Expanding reception in environmentally friendly power areas

- Developing spotlight on manageability and eco-accommodating materials

Comparative Analysis

Airtight Inspection Covers vs. Standard Covers

- Fixing capacity

- Solidness and life expectancy

- Cost contemplations

User Guides or Tutorials

Installation Guide

- Preparation: Clean the fixing surface.

- Positioning: Adjust the cover to the opening.

- Securing: Fix bolts or secure pivots.

- Testing: Check for spills utilizing pressure tests.

Maintenance Tips

- Consistently assess for mileage.

- Supplant gaskets intermittently.

- Guarantee bolts and pivots are greased up.

Conclusion

Airtight inspection covers are indispensable for keeping up with the honesty and wellbeing of different frameworks across numerous enterprises. By grasping their details, applications, advantages, and difficulties, partners can pursue informed choices to guarantee ideal execution and consistence with industry guidelines. The fate of airtight inspection covers looks encouraging with continuous developments and expanding industry reception.